Designing Molds for Extrusion of PC and PMMA Profiles

The design of molds for the extrusion of polycarbonate (PC) and methacrylate (PMMA) profiles allows the creation of customized final products. Plastic extrusion is a process made possible by specific machinery that uses molds for thermoplastic materials. The creation of these molds, through design technologies, is essential to obtain the final shape of the desired product.

The Advantages of the Plastic Extrusion Process

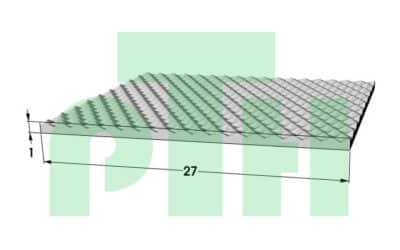

The plastic extrusion process, especially the extrusion of PMMA and PC, allows the production of plastic tubes and profiles used in various sectors. Thanks to this plastic shaping technique, methacrylate and polycarbonate in granular or powder form can be transformed into specific tubes and profiles used in lighting, automotive, medical devices, and much more. Extrusion involves feeding raw plastic material into a machine that heats and melts it, then pushes it at a constant pressure through a mold (or die) to give it shape. Finally, the finished product is cooled. The greatest advantage of the extrusion process is the customization of the shapes of the finished products. By using molds for thermoplastic materials, designed with software like CAD and CAM, extrusion can shape materials for a specific project.

PC and PMMA: What Kind of Materials Are They?

PC, or polycarbonate, and PMMA, or methacrylate, are thermoplastic materials used to produce a wide range of objects. Often replacing glass components, PC and PMMA are highly versatile polymers that are easy to shape through extrusion. For example, in the lighting sector, PMMA and PC are widely used for the construction of diffusers, screens, and lenses for LED lamps, thanks to their lightness, transparency, versatility, and high impact resistance.

How Are Molds Designed for the Extrusion Process?

Molds for thermoplastic materials or dies used in the extrusion process are elements that give shape to raw polymers. The dies are designed using specialized drawing and production software such as CAD and CAM, which stand for Computer-Aided Design and Computer-Aided Manufacturing. These professional digital drawing programs allow profile manufacturing companies to create molds for thermoplastic materials that give the extruded product the dimensions and geometry desired by the client.

Need a Company that Designs Molds for Extrusion of PC and PMMA Profiles? Contact us

Are you looking for a company that designs molds for extrusion of PC and PMMA profiles? Trust us at PTH Group, experts in PC and PMMA processing techniques. Our company has over thirty years of success stories, offering each client a team of experts able to find the perfect solution for any need. By using cutting-edge software, we can offer you a high-quality service for creating thermoplastic molds based on a customized project. Visit the PTH website or contact us by phone. You won’t regret it.