The extrusion of polycarbonate and methacrylate profiles, as well as other polymers for LED lighting and beyond, is a process that transforms plastic materials into real objects and profiles. Starting with powdered or granular polymers, it is possible to homogenize the materials and give them the desired shape. Without the extrusion of products, it would not be possible to create common items like shopping bags, packaging, ropes, and generally used plastic profiles.

What is extrusion?

Extrusion is a type of plastic processing used in the manufacturing sector. This process allows the shaping of thermoplastic materials, such as polycarbonate and methacrylate, to obtain various types of products, such as tubes and profiles for multiple applications. Plastic extrusion takes place in specific machines capable of transforming the materials using molds, known as dies, which are customized.

Polycarbonate and methacrylate: key features

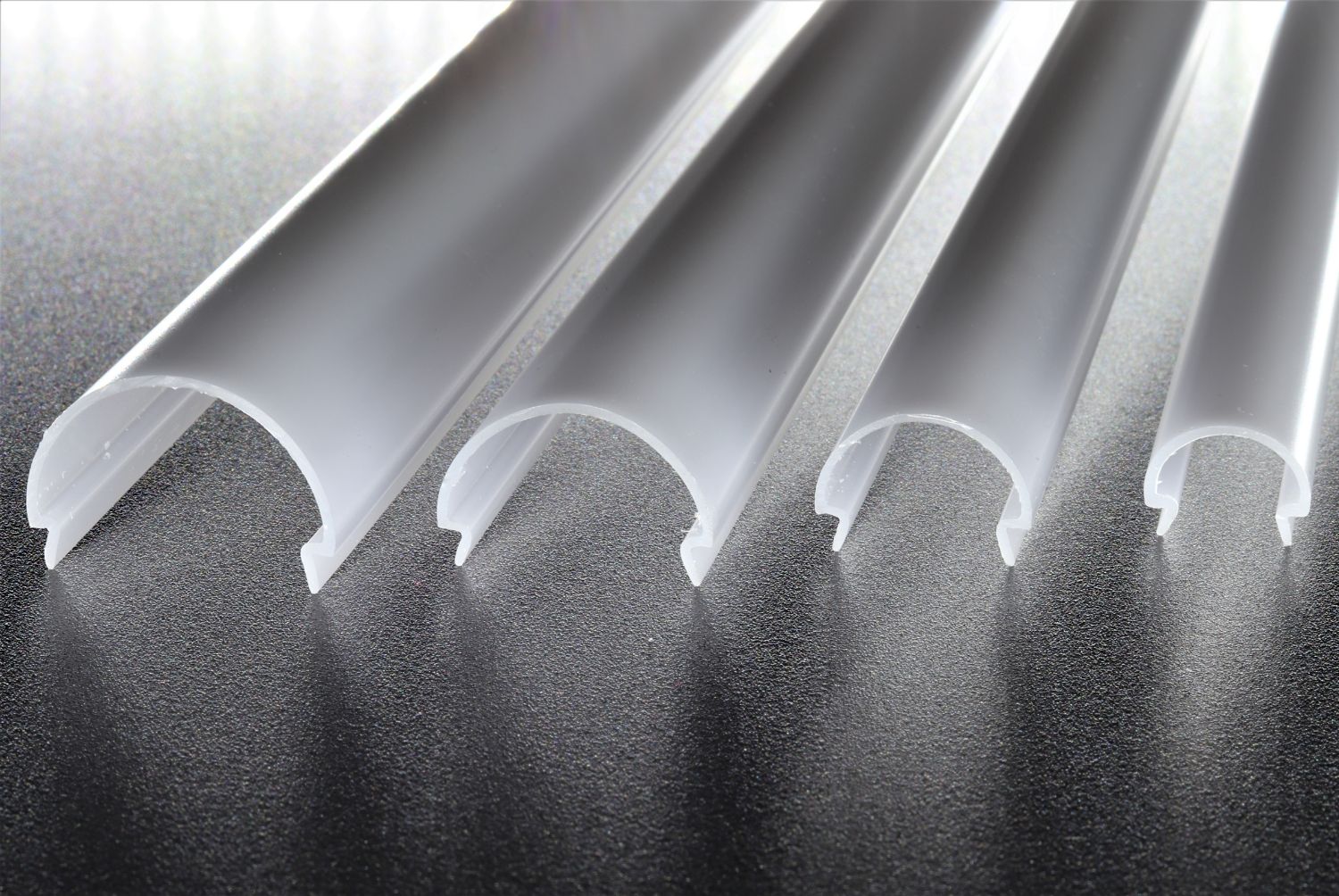

Polycarbonate and methacrylate are transparent thermoplastic materials, both usable in place of glass, but with different characteristics. Polycarbonate is a polymer derived from bisphenol A and is lighter and much more resistant than glass. It is an extremely easy-to-work plastic material, elastic, and particularly impact-resistant. Once extruded, polycarbonate can be used to create various objects such as:

- lamps;

- tubes;

- diffusers;

- covers;

- conduits;

- linear lenses.

Polycarbonate is less transparent than glass and methacrylate and, when exposed to UV rays, it yellows significantly. However, the great advantage of polycarbonate objects lies in their high mechanical resistance, especially when compared to glass.

- sheets;

- tubes;

- diffusers;

- linear lenses;

- covers.

This thermoplastic material, 100% recyclable, is more transparent than glass and extremely glossy and smooth. Compared to glass, methacrylate is lighter and 17 times more impact-resistant. However, PMMA is not a fire-resistant material, as it can burn at temperatures exceeding 460°C. The advantages of methacrylate objects include:

- transparency;

- a wide range of colors;

- excellent resistance to acids and cleaning products.

The choice between polycarbonate and methacrylate depends on the specific needs of each project.

Why choose plastic extrusion?

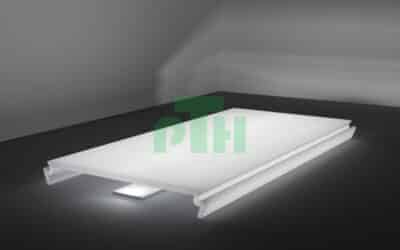

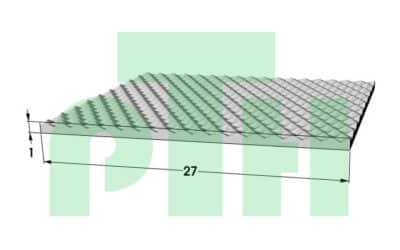

Plastic profile extrusion is essential to transform polymers into usable objects. Extrusion allows shaping any project that involves the use of thermoplastic materials. Most companies can create fully customized profiles and tubular elements that meet the specific needs of their clients.

Looking for a company that extrudes polycarbonate and methacrylate profiles and tubes? Contact us!

Do you need polycarbonate or methacrylate profiles or tubes? Trust us at PTH Group, specialists in thermoplastic material extrusion for years. Our company can ensure the production of custom molds, the extrusion of raw materials, and the creation of the profiles and tubes you need. PTH has the latest technologies for thermoplastic material extrusion and extensive experience in creating profiles for every industrial and commercial use. Contact us by phone or visit our website. You won’t regret it.