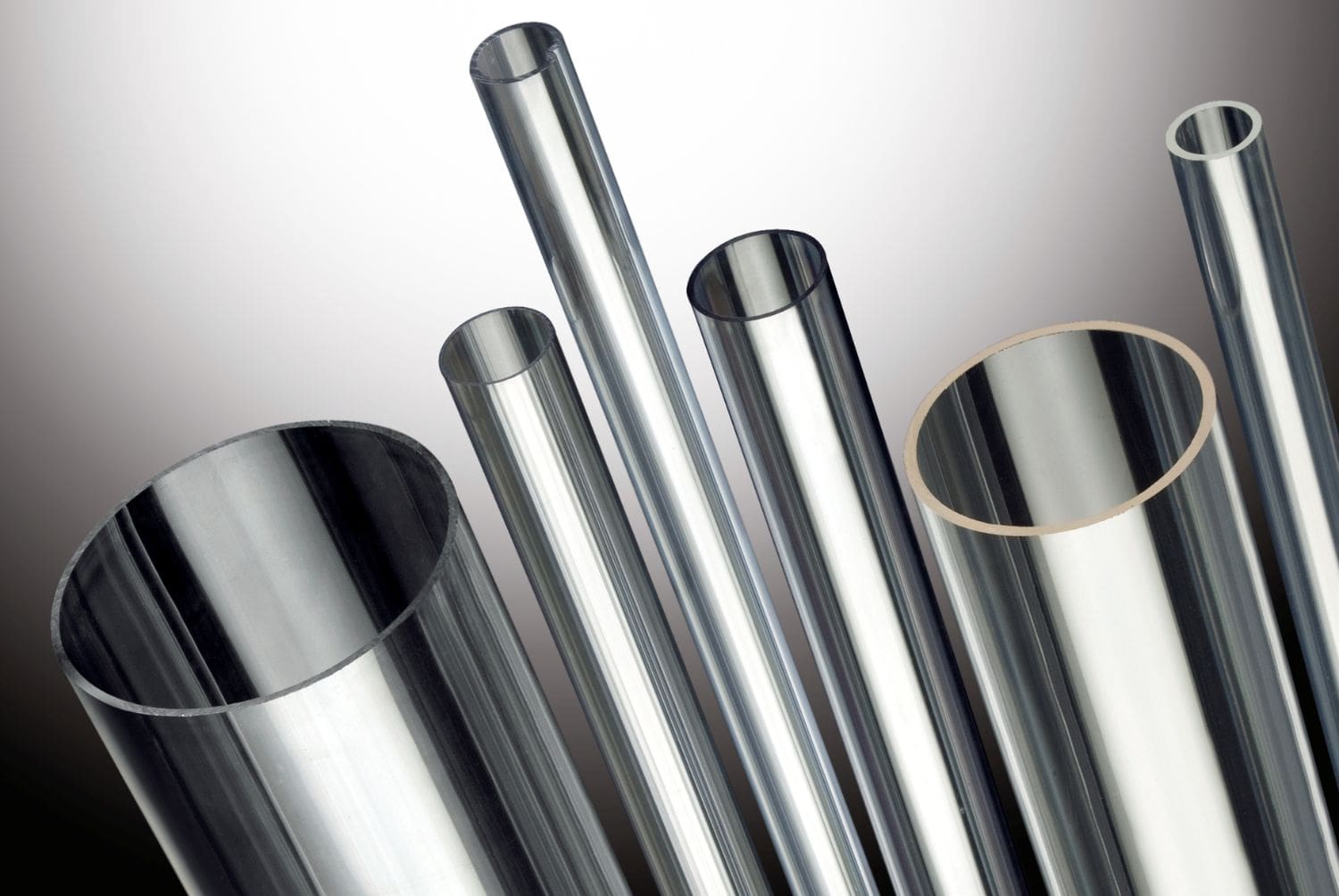

Polycarbonate and methacrylate tubes are useful for the production of numerous functional and design objects. Polycarbonate and PMMA are thermoplastic materials with specific technical and aesthetic properties, making polycarbonate and methacrylate tubes ideal for replacing glass tubes. Thermoplastic products find application in many sectors, particularly in the industrial sector for the production of design objects, lighting, and electronic items, as well as in the automotive sector. Let’s take a closer look at the details.

What Are Polycarbonate and Methacrylate Tubes?

Polycarbonate and methacrylate tubes are products made by extruding polymer granules or powder, usable as a finished product or as components for other projects. These transparent plastic tubes have strong mechanical resistance and are perfect for replacing glass tubes. Easy to process through extrusion techniques, thermoplastic materials can be transformed into polycarbonate and methacrylate tubes by creating custom molds designed for a specific project.

The Benefits of Using Polycarbonate and Methacrylate

Polycarbonate (PC) and methacrylate (PMMA or Plexiglas) are materials capable of efficiently replacing glass. While similar in appearance, their characteristics and practical applications differ significantly.

Sectors of Application for Polycarbonate and Methacrylate Tubes

The application sectors for thermoplastic tubes are numerous, including:

- The automotive sector, where tubes can be used as spare parts for vehicles;

- The electrical sector, where tubes can be used as coverings;

- The packaging sector;

- Lighting technology;

- The production of medical devices.

These sectors are just a few examples, as polycarbonate and methacrylate can be employed in many other fields. By considering the different characteristics of polycarbonate and methacrylate tubes, the most suitable material for the specific production sector can be chosen each time.

Looking for a Company That Manufactures Polycarbonate and Methacrylate Tubes? Let’s stay in touch

Do you need polycarbonate or methacrylate tubes? Trust us at PTH Group, a Lombard company specializing in the production of molds for plastic material extrusion. For over thirty years, we have offered services in the field of polycarbonate and methacrylate processing, using cutting-edge software. At PTH Group, we strive to meet your every need by collaborating on the realization of your customized project for polycarbonate and methacrylate tubes. Contact us by phone for more information or browse the range of services on our website. You won’t regret it.