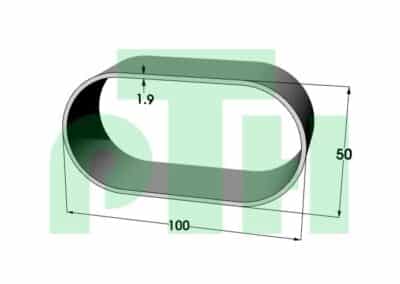

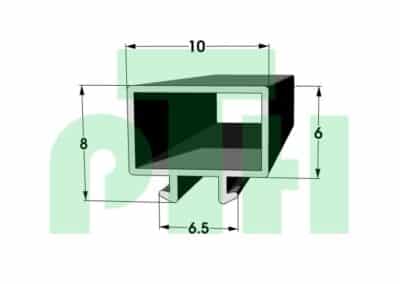

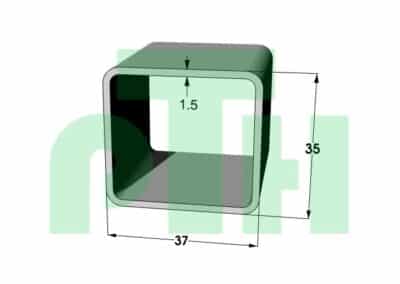

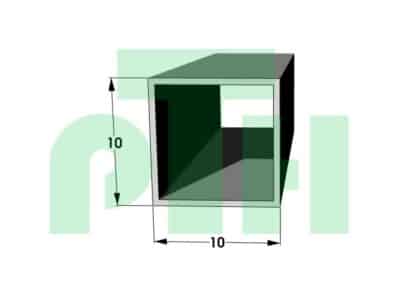

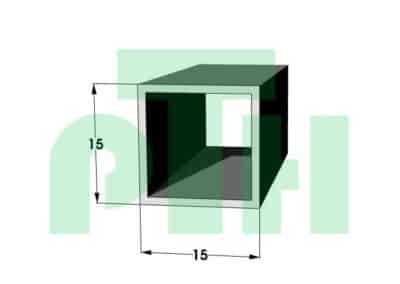

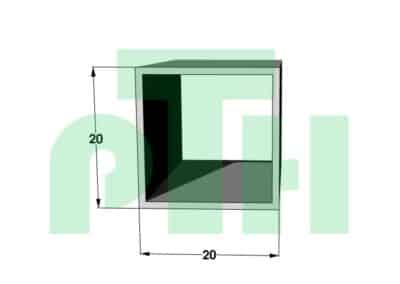

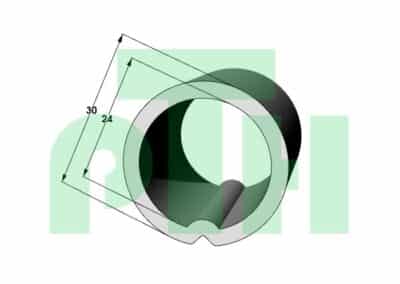

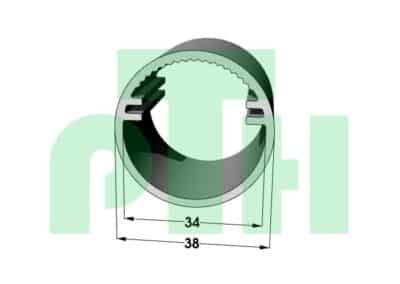

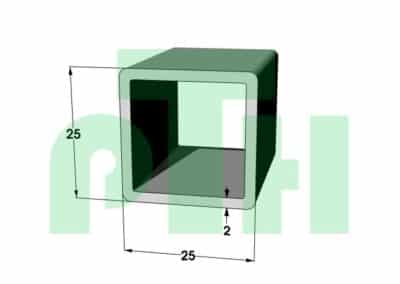

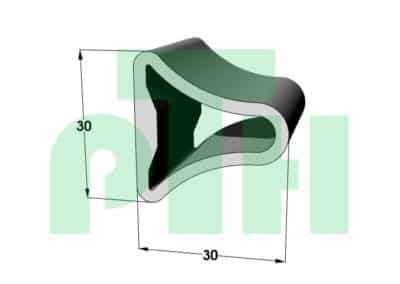

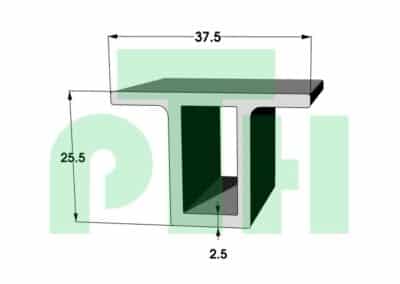

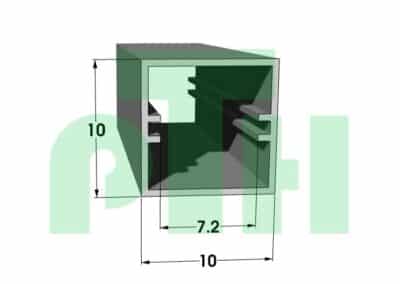

Closed Section Profiles in Polycarbonate (PC) and Polymethyl Methacrylate (PMMA) are extruded elements designed for various architectural and industrial applications. These profiles offer high mechanical strength, transparency, and durability. Available in different surface finishes, they can be adapted to numerous aesthetic and functional needs. Samples are available upon request for specific evaluations.

Available Samples

To help you choose the solution that best suits your needs, we offer samples of our profiles upon request. This will allow you to directly evaluate the available characteristics and finishes, ensuring you select the perfect profile for your project.

Typical Applications

PTH Group’s closed section profiles are used in a wide range of sectors, including:

- Construction and Architecture Covering structures: used for transparent or semi-transparent coverings in commercial and residential buildings.

- Lighting Light diffusers: used in lighting systems for uniform light diffusion, improving efficiency and visual comfort.

- Agricultural Sector Greenhouses: used for greenhouse coverings, offering transparency and protection from the elements.

Additional Features

- Impact Resistance Polycarbonate is known for its high impact resistance, making these profiles ideal for applications where safety is a priority.

- Versatility Suitable for a wide range of applications in both indoor and outdoor environments, thanks to weather resistance and tolerance to temperature variations.

Available Surfaces for Closed Section Profiles

-

Transparent

Perfect for applications requiring maximum transparency and visibility, such as lighting covers and displays.

-

Opal

Ideal for evenly diffusing light, reducing glare, and creating soft and pleasant lighting.

-

Satin

Offers an elegant and modern finish, combining transparency and opacity for a unique visual effect.

-

Colored

Available in a wide range of colors to meet the specific aesthetic needs of your projects.

-

Coextruded

Provides a combination of different materials in a single profile, offering unique properties such as added strength or special aesthetic effects.

-

Black & White

Ideal for contemporary design applications, where strong and sharp contrasts are required.