PMMA and Polycarbonate Tubes

PTH GROUP, thanks to the study and development of increasingly cutting-edge technologies, guarantees products of the highest quality in terms of surface uniformity, transparency, and light distribution. The technical department is also dedicated to researching the most efficient materials, which allows us to produce tubes that meet even the most demanding customer requirements. Plastic tubes are available in a wide range of outer diameters, from 4 mm to 300 mm, to meet the most diverse customer needs. Additionally, we have our own internal showroom with samples that can be sent upon request, allowing customers to directly evaluate finishes and quality.

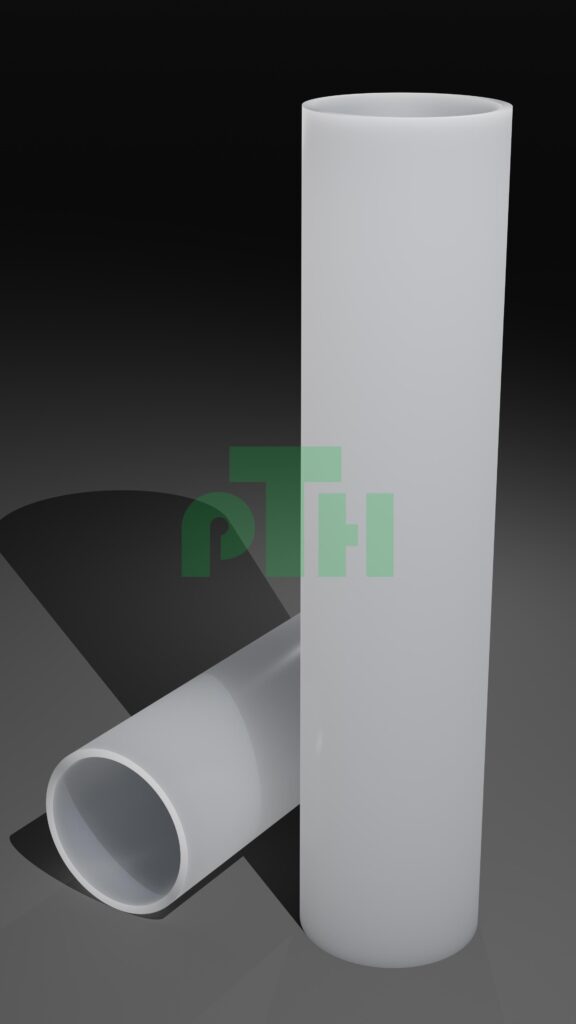

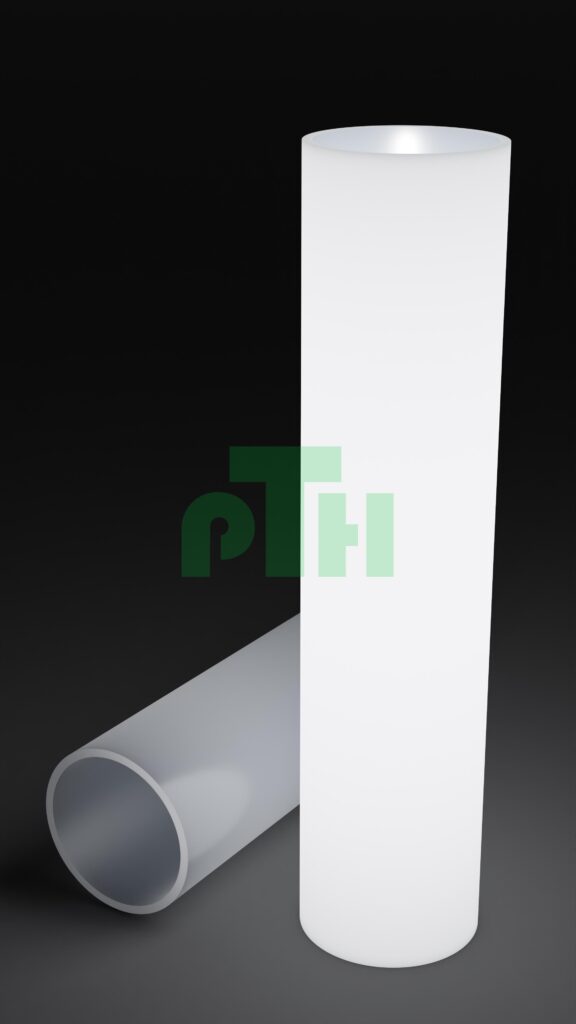

Polycarbonate Tubes

Polycarbonate Tubes are extruded with transparent, opal, satin, colored, prismatic, and co-extruded finishes. They feature UV stabilization, high impact resistance, and high-temperature resistance.

Upon request, we produce V0 FLAME RETARDANT Polycarbonate Tubes, primarily used in the transportation, automotive, and public building sectors, as well as Antibacterial Polycarbonate Tubes, Food-Grade (Food Contact use), Medical tubes, and UV Co-Extruded tubes.

Polycarbonate tubes are available in a wide range of outer diameters, ranging from 4 mm to 300 mm.

Technical Properties of Polycarbonate Tubes

- Excellent light transmission value

- UV stabilization

- Homogeneous light diffusion

- Flame retardant propagation

- Excellent fire resistance

- UL94 V2 and UL94 V0 certification

- High mechanical strength

- High impact resistance

- Chemical resistance

- Tensile and yield strength

- Resistance to high temperatures

Polycarbonate Tube Applications

- Tubes for Lighting

- Tubes for LED

- Tubes for the Food and Medical Industry

- Tubes for Railway Stations and Airports

- Tubes for Refrigeration and Greenhouses

- Tubes for Oil and Gas

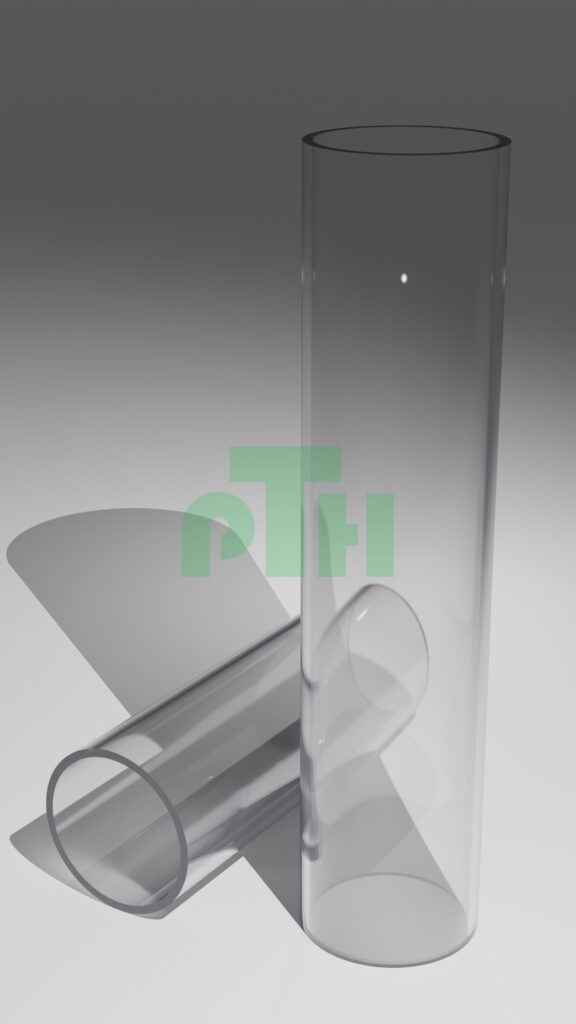

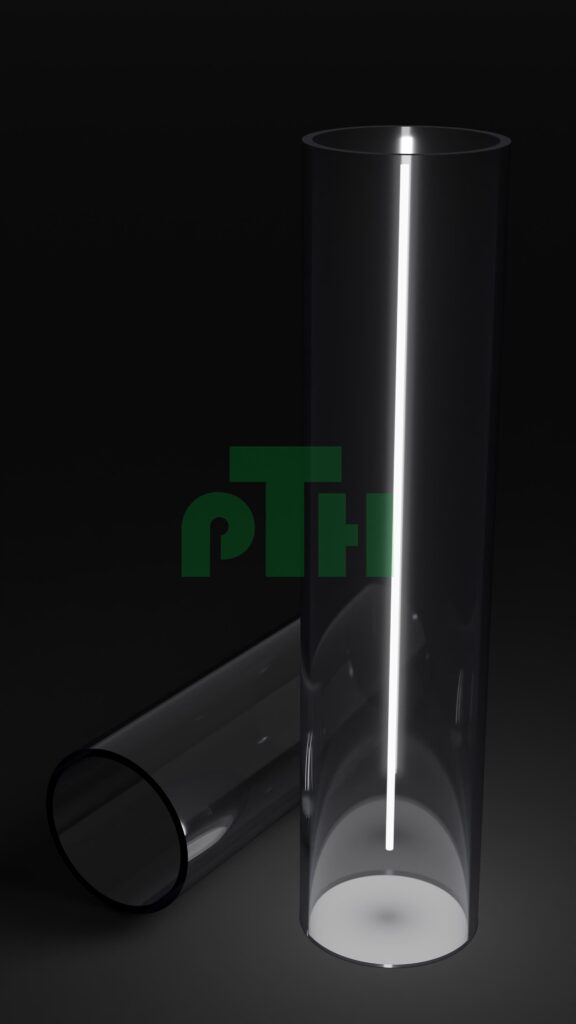

PMMA Tubes

Methacrylate (PMMA) tubes are extruded with transparent, opal, and satin finishes. They feature high light transmission, no yellowing, transparency, and a breaking point superior to glass.

PMMA tubes are available in a wide range of outer diameters, ranging from 4 mm to 300 mm.

Technical Properties of PMMA Tubes

- Excellent light transmission value

- UV stabilization

- Homogeneous light diffusion

- Flame retardant propagation

- Excellent fire resistance

- UL94 V2 and UL94 V0 certification

- High mechanical strength

- High impact resistance

- Chemical resistance

- Tensile and yield strength

- Resistance to high temperatures

PMMA Tube Applications

- Tubes for Lighting

- Tubes for LED

- Tubes for Design and Furniture

- Tubes for Liquid Transport

- Tubes for Level Indicators

Available Diameters for PMMA and Polycarbonate Tubes

*Also available with internal prismatic structure.

Wall thickness and other diameters available upon request.

**Indicative, but may vary depending on thickness.

| Outer - Ø in mm | Min. production volume (m) |

|---|---|

| 4 | 2000 |

| 4,7 | 2000 |

| 5 | 2000 |

| 6 | 1500 |

| 7 | 1500 |

| 8 | 1500 |

| 9 | 1500 |

| 9,5 | 1500 |

| 10 | 1500 |

| 11 | 1000 |

| 12 | 1000 |

| 13 | 1000 |

| 14 | 1000 |

| 15 | 1000 |

| 15,5 | 1000 |

| 16 | 1000 |

| 17 | 1000 |

| 18 | 1000 |

| 19 | 1000 |

| 20 | 1000 |

| 20,5 | 1000 |

| 21 | 1000 |

| 22 | 1000 |

| 23 | 1000 |

| 24 | 1000 |

| 25 | 1000 |

| 25,4 | 1000 |

| 26 | 1000 |

| 27 | 1000 |

| 28* | 1000 |

| 30* | 1000 |

| 32* | 1000 |

| 32,5* | 1000 |

| 33* | 1000 |

| 34* | 1000 |

| 35* | 1000 |

| 36* | 1000 |

| 38* | 1000 |

| 40* | 500 |

| 42,5* | 500 |

| 44* | 500 |

| 45* | 500 |

| 50* | 500 |

| 52* | 500 |

| 56* | 500 |

| 59* | 500 |

| 60* | 500 |

| 63* | 500 |

| 64* | 500 |

| 65* | 500 |

| 66* | 500 |

| 67* | 500 |

| 68* | 500 |

| 70* | 250 |

| 75* | 250 |

| 78* | 250 |

| 80* | 250 |

| 83* | 250 |

| 84* | 250 |

| 90* | 250 |

| 95* | 250 |

| 96* | 250 |

| 100* | 250 |

| 110* | 250 |

| 120* | 250 |

| 125 | 250 |

| 130 | 250 |

| 133 | 250 |

| 134 | 250 |

| 140 | 250 |

| 145 | 250 |

| 150 | 250 |

| 152 | 250 |

| 160 | 250 |

| 170 | 250 |

| 178 | 250 |

| 180 | 250 |

| 185 | 250 |

| 200 | 250 |

| 230 | 250 |

| 240 | 250 |

| 250 | 250 |

| 300 | 250 |

Customized Processing and Tailored Packaging

-

Precise cutting

-

Drilling*

-

Prototyping

-

Protective coating application

-

Double-sided adhesive application

-

Special packaging

* Only for PC and subject to approval by the technical department